Call us now:

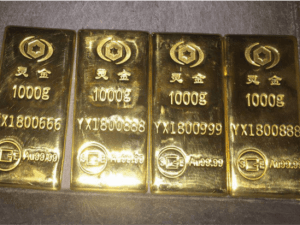

In some domestic smelters by cyanide gold sludge obtained from the crude gold, gold content of up to 15-37%, assemble not more than 50%; mercury paste distillation out of the crude gold in 50%-70%; heavy sand refining crude gold gold content of up to 80%-92%. Because the crude gold contains more impurities, so need to further refining, gold and silver refining raw materials are the following four kinds.

1. gold sludge / gold-laden carbon electrolysis of gold sludge after the replacement of cyanide precious liquid in the mining smelter;

2. Lead smelter lead anode sludge treatment produced by the gold and silver alloy plate;

3. Gold and silver alloy plates from copper anode sludge treatment in copper smelters;

4. Crude gold and silver recovered from other industries.

The essence of the chlorinated gold dissolution method is sodium chlorate will hydrochloric acid oxidation decomposition to produce new ecological chlorine, the new ecological chlorine has a strong oxidation ability and chemical activity, can be gold oxidation to generate chloride and into the liquid phase. In the role of sodium chlorate, hydrochloric acid, gold dissolution to generate soluble chloride complex acid or chloride complexate.

To the chlorine leaching reaction kettle add appropriate amount of water, hydrochloric acid, heating, put into the gold powder after the debris, closed reaction kettle, add sodium chlorate solution. Chlorine leaching kettle control liquid-solid ratio of 8:1, temperature 85 ~ 90 ℃. Through the detection and control of leaching temperature, sodium chlorate dosage and other parameters, the impurity metal is selectively removed.

Through this reaction, the gold in the gold sludge is transferred from the solid phase to the liquid phase, while the small amount of silver remaining in the material generates insoluble silver chloride to remain in the solid phase; replacement treatment is carried out (adding excess Fe/Zn), after which hydrochloric acid is added for silver recovery, and the recovered silver can enter the silver electrolysis process for smelting and plate casting.