Call us now:

Gold is a natural product that can not be synthesized, it is divided into raw gold and cooked gold. Gold after purification to reach a fairly high purity of gold is called pure gold, generally refers to the gold that reaches 99.6% or more color. After the purification of gold, generally higher purity, some can be directly used in industrial production.

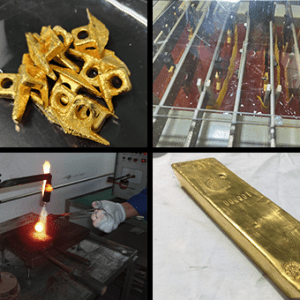

1、How to refine gold

Single flotation is suitable for processing coarse and medium grain natural gold iron ore. After crushing, the ore enters into the ball mill and is ground finely as a slurry and then enters into flotation. Amalgamated flotation is suitable for processing natural gold embedded in coarse particle size, stored in pyrite and other sulfide ores. Different from single flotation after grinding with mercury plate for gold recovery, the recovery rate can reach 30-45%. Belt conveying into the tailing field; not larger than the screen hole of the mineral sand through the public orchestrator into 1-3 sections of round jigger, after 3 sections of jigger concentrate from the flow for shaking bed, for coarse, fine, sweeping selection, production out of fine sand ore. This method is mostly used for flowing sand ore, and the finely crushed ore can also be applied.

2, the method of refining gold amalgamation gold purification method is introduced

This is actually an ancient gold purification method, as long as one has the patience, one can come to mention a very high purity, the specific method is as follows.

Gold + mercury + water, constantly grinding until there is no gold particles, gold and mercury to generate intermetallic compounds. The sulfur powder and has been amalgamated gold grinding mix, air heating peaking, this time, a surplus of mercury volatilization, base metal first generated metal sulfide, the later will generate metal oxides. Repeat the above operation several times plus borax melting into gold ingots base metal oxides and borax reaction to generate low melting point material, floating in the upper layer of the liquid, pure gold in the bottom will use this method to prevent mercury vapor poisoning.

3, the method of refining gold wet gold purification process introduction

Wet gold purification process method is all use aqua regia dissolved gold, and then add reducing agent to reduce the gold, or as into the masking agent complex interference material, followed by the extraction method, the original agent or extractant. The invention breaks through the traditional process, high temperature melting and other simple purification process, to get higher quality gold. Compared with the existing technology, the present invention is with high product purity, lower production costs, simple and practical process. There is another is the wet purification of gold process, it is so the crude gold in the container, add to the newly prepared aqua regia submerged crude gold, and then heated dissolved 15 ~ 25 minutes, if the crude gold is not dissolved, you can add aqua regia repeatedly dissolved, until dissolved completely.

In fact, part of the gold is a series of gold ore refining, there is a way is through the electronic waste refining out, such as: computer boards, cell phone boards and a variety of loose parts have gold, Taishan mention gold is actually a professional refining series of various gold ore and gold-containing electronic waste refining gold method.