Call us now:

Gold Extraction from E-Waste Using Aqua Regia

Gold Extraction from E-Waste Using Aqua Regia Aqua regia stripping is a recycling method that dissolves the gold plating in e-waste…

Gold Extraction from E-Waste Using Aqua Regia Aqua regia stripping is a recycling method that dissolves the gold plating in e-waste…

Pyrometallurgy of lead anode mud The pyrometallurgical treatment of lead anode mud mainly recovers precious metals through reduction smelting, oxidation refining and electrolytic extraction. First,…

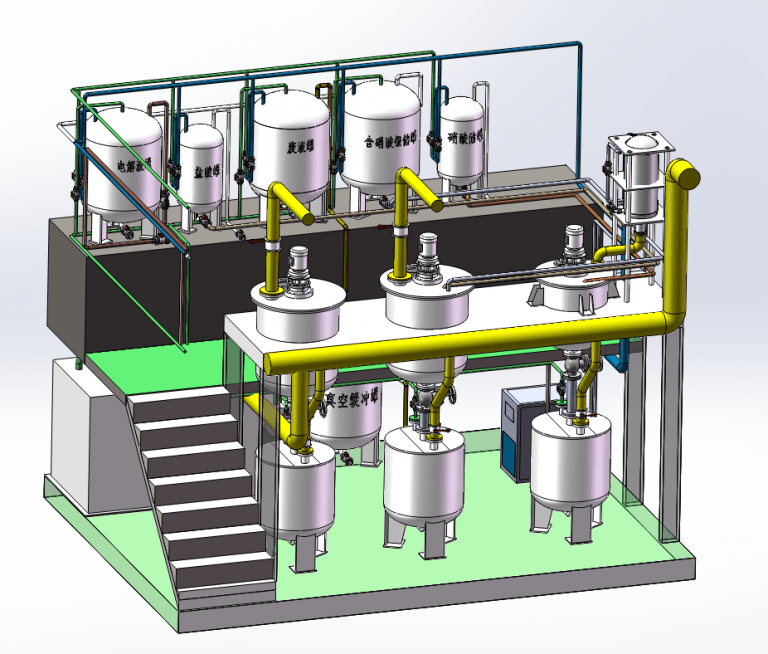

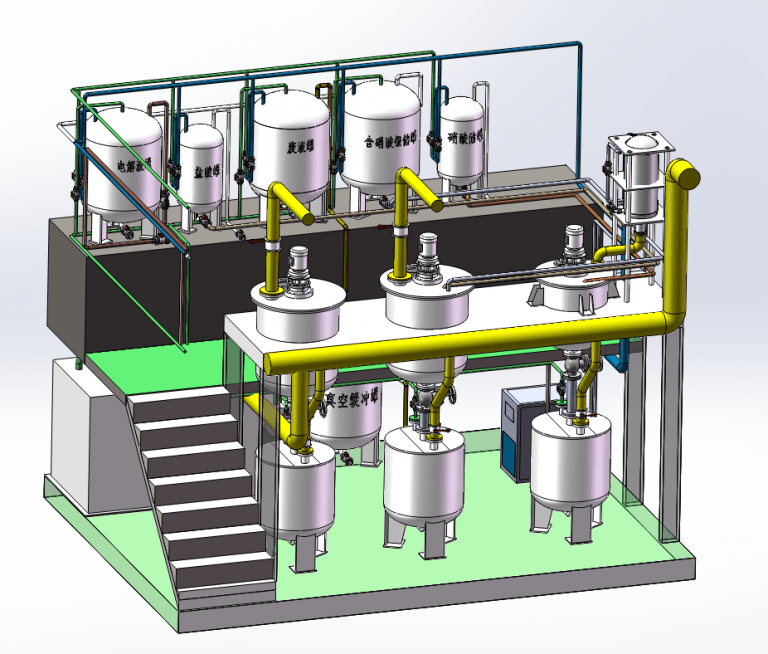

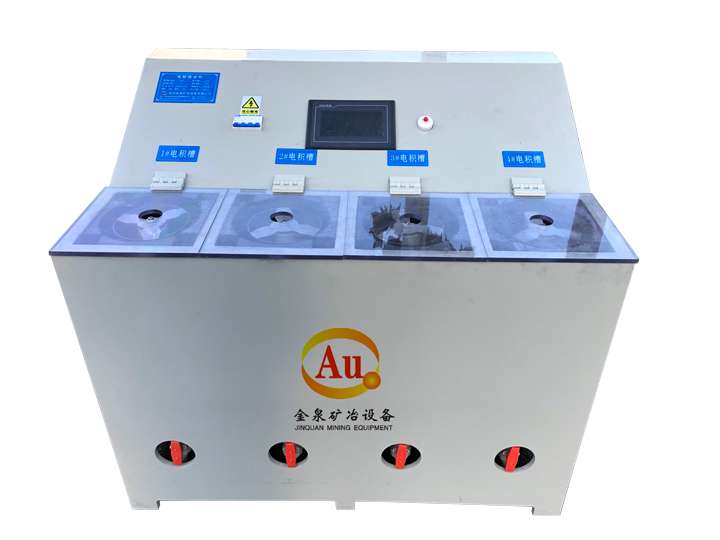

Gold-loaded carbon electrolysis process First, the gold-loaded carbon is pre-treated and screened to separate carbon powder and fine particles and enter the carbon storage tank.…

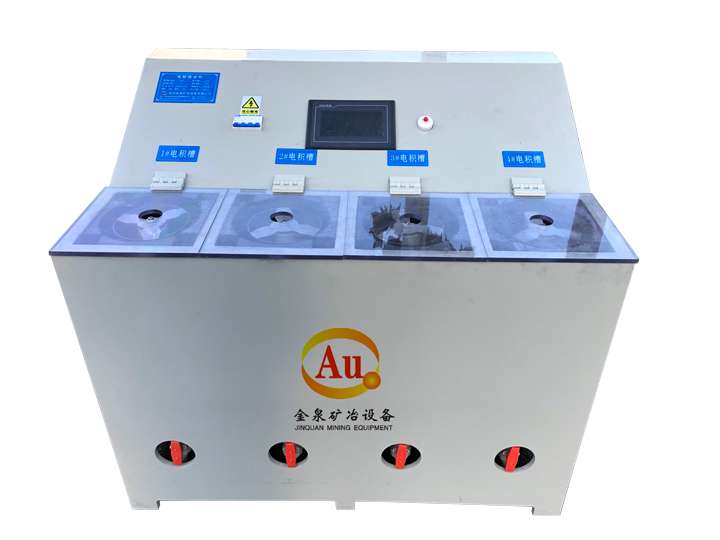

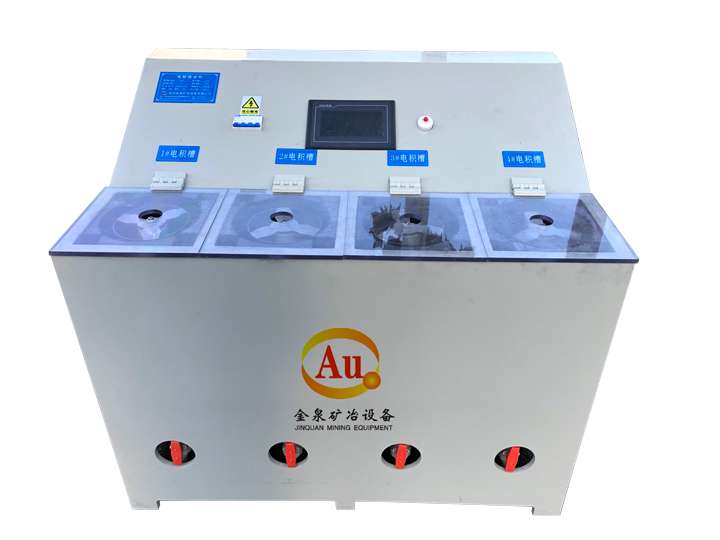

Refining silver from silver nitrate by electrolysis Electrolysis is a simple and environmentally friendly method that directly extracts high-purity silver through electrolysis. The specific operation…

Common carriers for supported palladium catalysts include alumina, cordierite (2MgO·Al2O3·SiO2), silica gel, activated carbon and zeolite. When selecting a process to recover palladium, the distribution…

Composition of sludge after lead electrolysis The anode mud produced from lead electrolysis contains various valuable metals, including precious metals (gold, silver), rare metals (selenium,…

Economic Value Palladium Price: Approximately $65 per gram (as of mid-2024). Platinum Price: Approximately $33 per gram (as of mid-2024). Gold Price: Approximately $60 per…

Refining iridium powder is a complex process that involves multiple steps of chemical and metallurgical techniques. Here are the basic steps for refining iridium powder:…

Efficient Silver Recovery: Efficient Silver Recovery from Waste Film via Centrifugal Electrodeposition While traditional film usage has declined in…