Principle of metal electrolysis

The basic principle of electrolysis (anode dissolution, cathode deposition),

electrolyte composition, purity control, and recovery efficiency.

Electrolysis is the process of using electric current to drive non-spontaneous

chemical reactions. In gold and silver electrolysis, the anode is usually an alloy or

crude metal containing gold and silver, and the cathode is a pure metal flake.The

electrolyte must effectively dissolve metal ions, typically using solutions such as

silver nitrate or potassium gold cyanide. During this electrochemical process, as

electrical current flows through the system, the anode metal undergoes dissolution

while the liberated ions migrate to and deposit onto the cathode, thereby achieving

metal purification.

Take gold and silver electrolysis as an example: Gold and silver electrolysis

technology achieves efficient purification of precious metals through electrochemical

redox reactions: the anode is a crude metal containing gold and silver (such as an

alloy or scrap) that dissolves under the action of electric current

(Ag→Ag⁺+e⁻, Au→Au³⁺+3e⁻),

and the metal ions migrate to the cathode and are reduced and deposited as high-purity

metals (Ag⁺+e⁻→Ag, Au³⁺+3e⁻→Au).

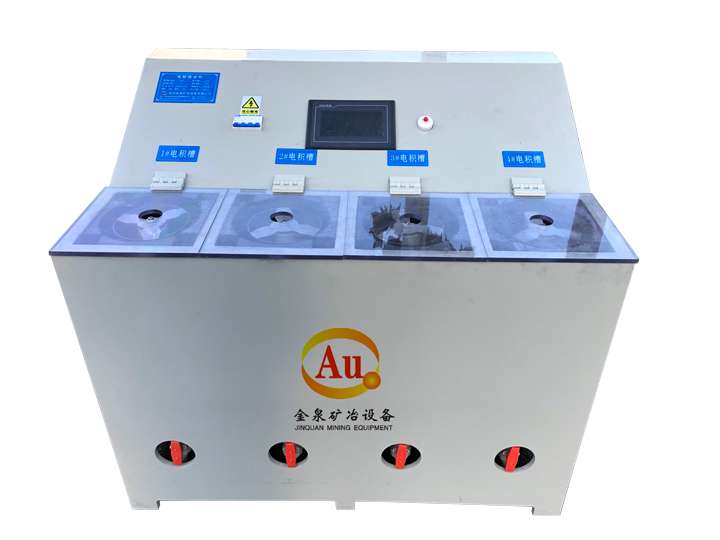

Metal electrolysis equipment can be flexibly expanded according to production needs,

with high purity, low loss and high metal recovery rate. The electrolysis equipment can be

modularly designed and is suitable for precious metal refineries, small to large gold refining

companies and laboratory applications.Principle of metal electrolysis vido

Call us now: