Call us now:

Precious Metal Reaction Vessel Introduction

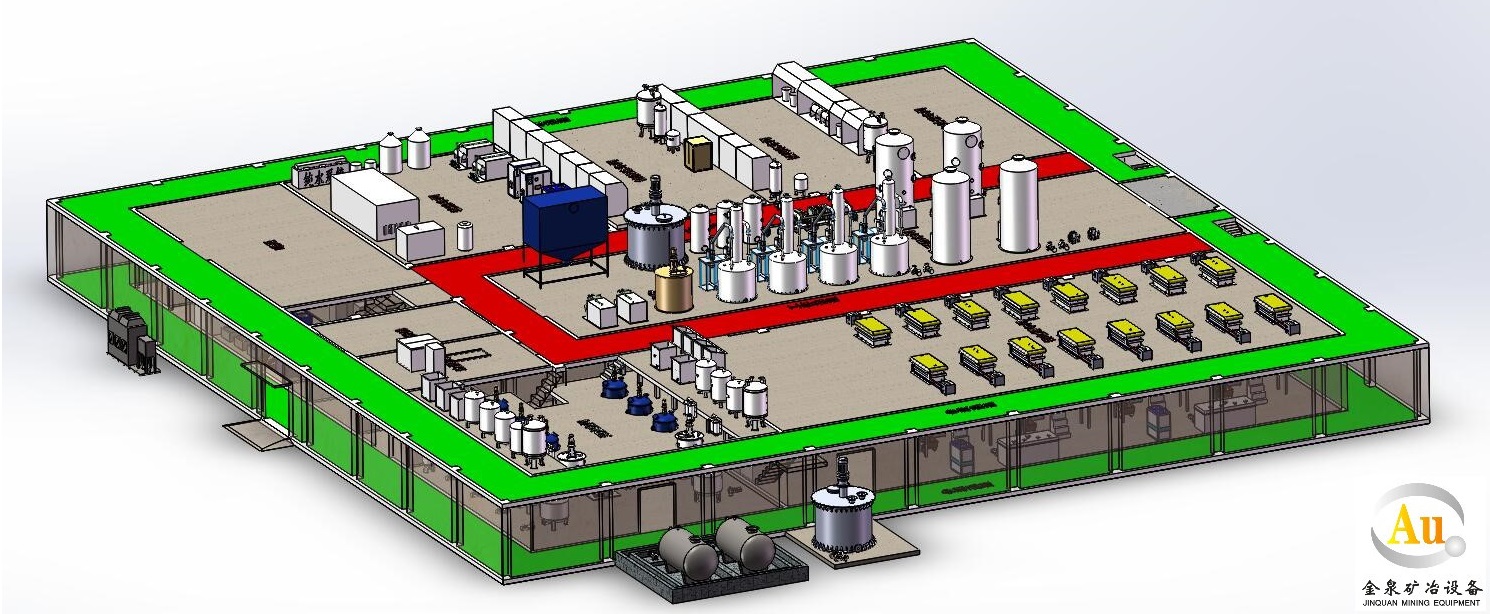

Precious Metal Reaction Vessel Introduction Product Overview Our Precious Metal Reaction Vessel is a high-performance chemical processing system specifically designed for refining and extracting precious metals (Au, Ag, Pt, Pd,