Silver sulfide (Ag₂S) electrolytic recovery

Recovery of silver from silver sulfide (Ag₂S) by electrolysis is an effective silver extraction

method that includes several key steps: raw material preparation, leaching, electrolysis, silver

deposition, tailings treatment, and product refining. First, the silver sulfide ore is crushed and

concentrated, then leached with a sodium cyanide (NaCN) solution to form a soluble silver-cyanide

complex:

Ag₂S + 4NaCN + O₂ + 2H₂O → 2Na[Ag(CN)₂] + NaOH + S

This reaction converts the silver sulfide into a soluble form for further processing. The leaching

process is carried out under alkaline conditions (pH 10-11) and the temperature is controlled at

20-30°C to optimize efficiency.

Next, workers electrolyze the silver-cyanide solution in an electrolytic cell. At the cathode, silver ions reduce to metallic silver (Ag(CN)₂⁻ + e⁻ → Ag + 2CN⁻), which deposits on the cathode surface. Workers periodically strip, wash, and dry the deposited silver to obtain high-purity silver. At the same time, hydroxide ions oxidize at the anode to produce oxygen (4OH⁻ → 2H₂O + O₂ + 4e⁻). Workers operate the electrolysis process at a current density of 100-200 A/m², a cell voltage of 1-2 V, and a temperature of 20-30°C to ensure optimal silver recovery.

After electrolysis, workers process the tailings, which contain trace amounts of silver and other impurities, to recover the residual silver. They achieve this through adsorption on activated carbon or chemical precipitation, such as adding sodium chloride to form AgCl.

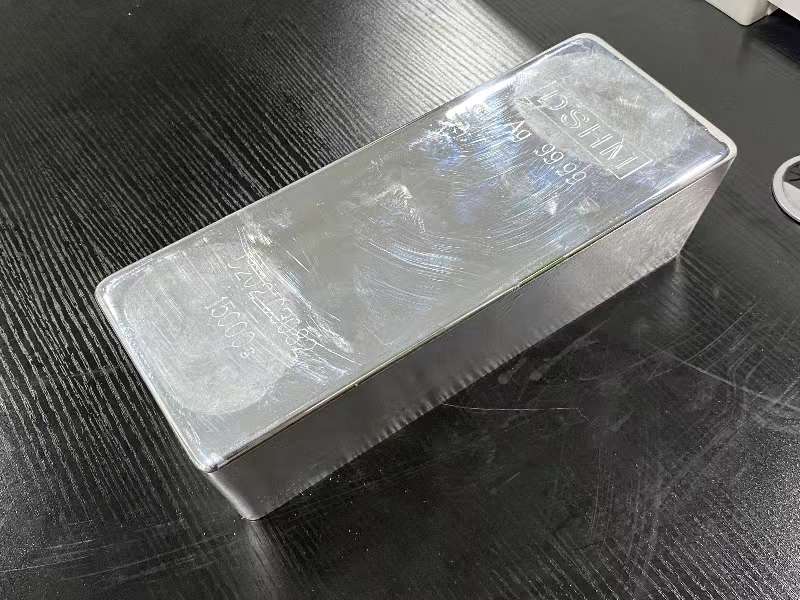

Finally, the recovered silver needs to be further refined to obtain higher purity. Electrolytic refining uses crude silver as the anode and pure silver as the cathode in a silver nitrate solution to further purify the metal. The entire process ensures efficient silver recovery and also reduces environmental impact, making it a sustainable method for recovering silver from sulfide ores.

Silver sulfide (Ag₂S) electrolytic recovery

Call us now: