Call us now:

CIL carbon leaching method of gold extraction process mainly includes impurity removal, concentration before leaching, leaching and adsorption, desorption electrowinning, wet smelting, activated carbon regeneration, tailing press filter, sewage treatment and other stages.

1, pulp debris: cyanide pulp before adsorption to remove impurities such as wood chips, to avoid wood chips adsorption of gold in the pulp and prevent it from mixing into the rich carbon, and to prevent wood chips from blocking the carbon sieve.

2、Concentration before leaching; usually, in order to achieve a suitable leaching concentration, the pulp should be dewatered through a thickener before leaching, the concentration level will not only affect the leaching time, but also affect the suspension state of the activated carbon.

3、Leaching and adsorption: the slurry after debinding and concentration is punched into the leaching tank arranged in a ladder, generally configured in series by 5-8 tanks, the first two tanks are added with cyanide, the last five tanks are added with activated carbon, the slurry and activated carbon are adsorbed in counter-current, the activated carbon becomes gold-carrying carbon due to the adsorption of gold in the slurry, after the adsorption is completed, the slurry containing gold-carrying carbon is given to the carbon lifting screen through the air lifter, and the carbon lifting screen separates the activated carbon and the slurry. Separate.

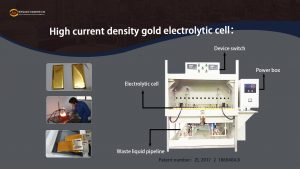

4、Desorption electrolysis: usually the desorption of gold-bearing carbon and the electrolytic deposition of liquid gold are done in a closed system, under high temperature and high pressure, the gold-bearing carbon can be rapidly desorbed and electrolyzed into gold sludge and poor carbon. The main equipment includes desorption column, acid washing tank, heater, filter, desorption liquid tank, electrolytic tank, etc.

5、Smelting: The obtained gold sludge can be directly smelted out of gold ingots after simple pickling and impurity removal. Using wet metallurgy, gold ingots can reach 99.99% purity or more

6、Renewal of activated carbon: After desorption, the activated carbon is first acid-washed to remove carbonates and other aggregates, and then thermally activated to restore the adsorption activity of the carbon after several times of return to use, after which it can be recycled. The main equipment includes activated carbon regeneration kiln, water quenching tank, fine carbon separation sieve, etc.