Call us now:

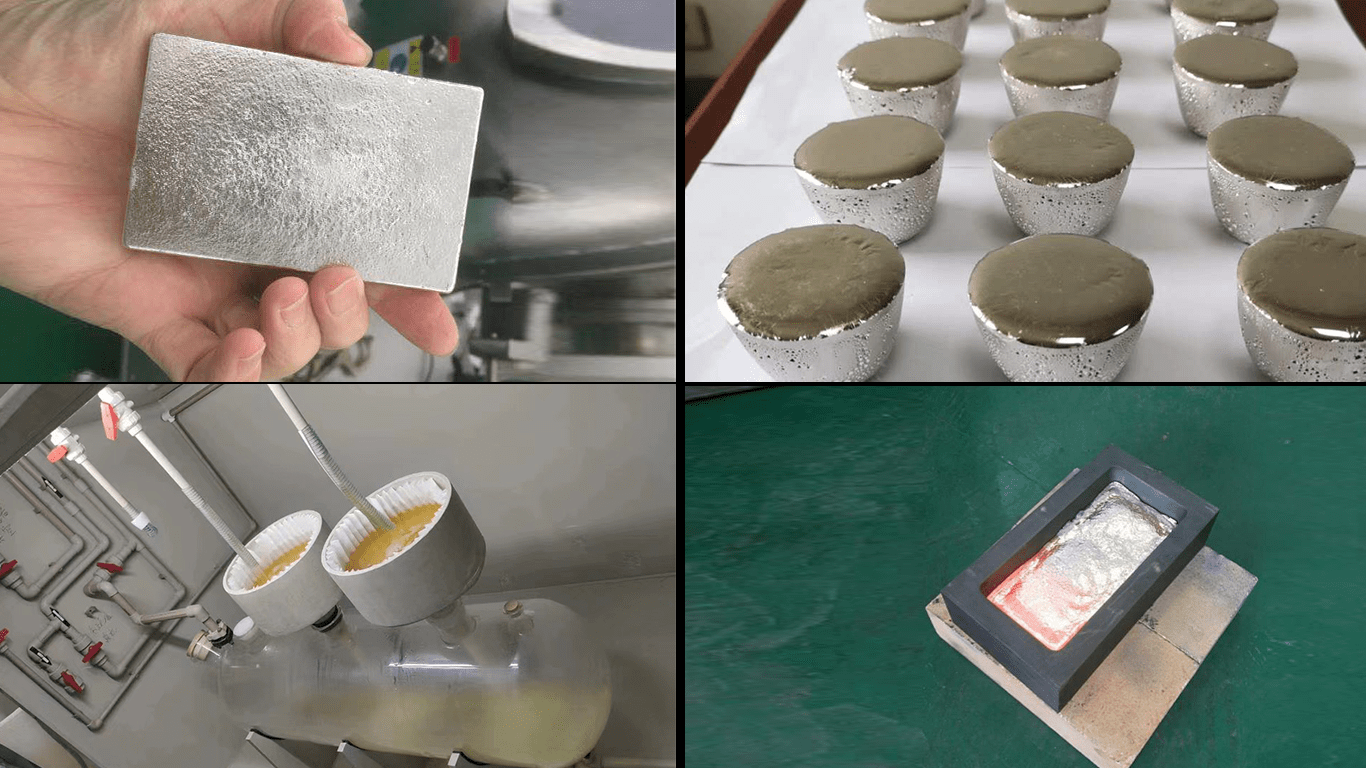

Platinum Refining: From Leaching to Roasting

Platinum refining involves a series of steps to obtain high-purity platinum.

Here's a concise overview:

1.Leaching: Platinum and other metals are dissolved in a solution with strong oxidants

like aqua regia and NaClO3. Silver forms a precipitate while platinum dissolves. Reaction:

3Pt+2NaClO3+18HCl→3H2PtCl6+2NaCl+6H2O

2.Neutralization: Adjust the high-acidity leaching solution to pH 1 using NaOH and wash

the residue with hydrochloric acid.Platinum Refining: From Leaching to Roasting

3.Platinum Precipitation: Add ammonium chloride to the solution until no more yellow

precipitate forms. Then, cool, filter, and wash the residue with 10% ammonium chloride. Reaction:

H2PtCl6+2NH4Cl→(NH4)2PtCl6↓+2HCl

4.Roasting: Heat the filtered residue to decompose ammonium chloroplatinate into sponge

platinum. Repeat chlorination, neutralization, and roasting until pure platinum powder is obtained.

(NH4)2PtCl6→Heating3Pt+2NH4Cl+16HCl+2N2↑

Platinum refining is critical for various industrial applications, ensuring the metal's purity and quality.

Equipment needed for platinum refining: reactors and other anti-corrosion chemical equipment.

Platinum Refining: From Leaching to Roasting,learn more