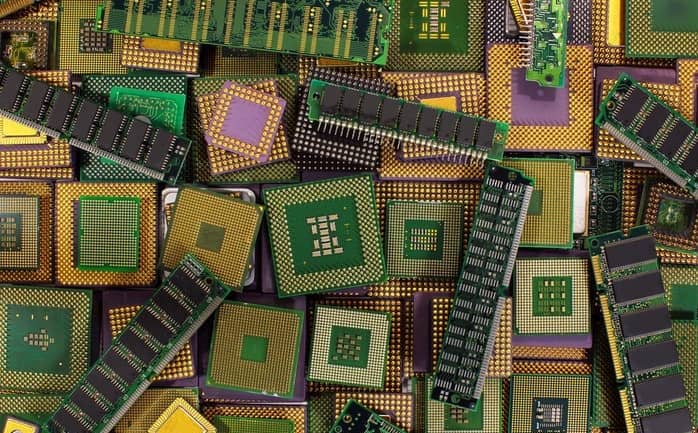

CPU Precious Metal Recycling Solutions

Most electronic waste recyclers currently rely on pyrometallurgy – a process that involves

burning entire circuit boards in furnaces – to recover precious metals from CPUs. However, this

method often sacrifices efficiency and accessibility, particularly for small-to-medium recyclers

seeking direct control over gold, silver, and palladium recovery.

To address this gap, we developed a streamlined hydrometallurgical system that enables users

to extract gold, silver, palladium, platinum, indium, and iridium from e-waste with minimal training.

By replacing complex pyro-metallurgical processes with chemical leaching and electrochemical refinement,

our technology empowers recyclers to bypass traditional smelting dependencies while achieving 99.95%

gold recovery rates. Operators simply follow automated protocols to process materials, eliminating

the need for specialized metallurgical expertise.

This system excels at recovering gold from plated components in obsolete electronics, including:

- Mobile phone circuit boards and computer CPUs/motherboards

- Discarded DVDs, gaming consoles, and home appliances

- Electroplating factory scraps and printed circuit board trimmings

Beyond gold recovery, the refined output meets 99.99% purity standards for direct industrial reuse.

As pioneers in sustainable e-waste processing, we integrate three core competencies:

Custom Hydrometallurgical Systems: Tailored reactors for Au/Ag/Pd extraction

Closed-Loop Refinement: ISO-certified purification workflows

Turnkey Implementation: Workshop design, non-standard equipment fabrication, and staff training

Recent deployments demonstrate the system’s versatility:

Transitioning to our technology not only cuts processing costs by 30-50% but also aligns with circular

economy goals by diverting 98% of e-waste from landfills.CPU Precious Metal Recycling Solutions

VIDO

Call us now: