Call us now:

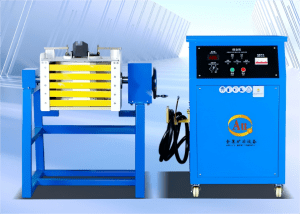

20KG Tilting Type Gold Melting Furnace

Gold Melting Furnace (Tilting Type Gold Melting Furnace) Specification Parameter: 20KG Main Parameters Rated Temperature: 1000℃ Temperature Fluctuation: ±1℃ Heating Element: Electric heating wire Working Chamber Dimension: 600×400×300mm Electrical Control: