Call us now:

Jinquan Electrochemical Deposition Equipment

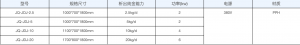

Jinquan Electrochemical Deposition Equipment The electrochemical deposition system has revolutionized traditional metallurgical processes through dynamic flow field control technology and is widely used in