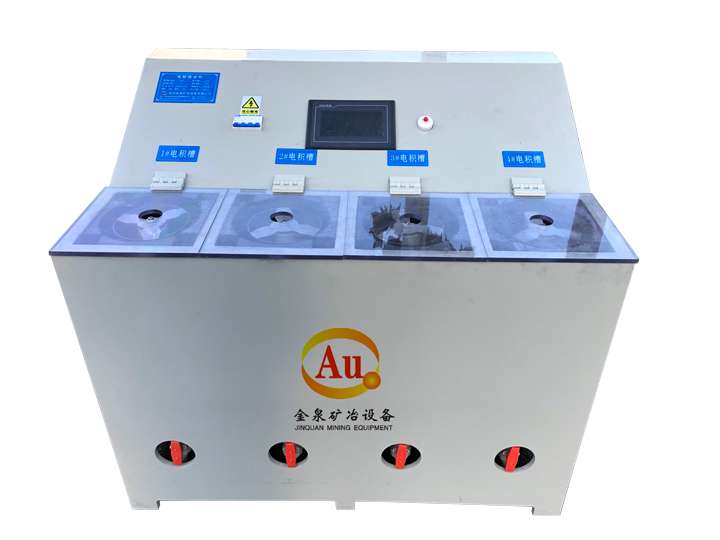

Jinquan Electrolysis - Cyclone Electrowinning Equipment

Cyclone electrowinning equipment is widely used in gold plating solution,

gold stripping solution, gold ore heap leaching, spraying solution to extract gold,

fixing solution to extract silver, copper oxide ore heap leaching solution, etching

solution to extract copper, tin stripping solution to extract tin... extract metals

from metal-containing solutions!

Rectifier power supply: 6V200A, rotary motor power: 25W, circulation pump

power: 80W

Cyclone electrolysis technology is based on the difference in theoretical precipitation

potential (E¢) of each metal ion, that is, as long as the metal to be extracted has a large

potential difference with other metal ions in the solution system, the metal with a more

positive potential is easy to precipitate preferentially at the cathode.

The key is to eliminate the adverse factors such as concentration polarization on

electrolysis through high-speed solution flow, avoiding the limitations of the traditional

electrolysis process affected by multiple factors (ion concentration, precipitation potential,

concentration polarization, overpotential, pH value, etc.), and can produce high-quality

metal products through simple technical conditions.

Process parameters:

Working voltage: usually between 4 and 6 volts to ensure low-voltage operation,

reduce energy consumption, and ensure the selectivity of metal reduction reactions.

Current density: designed between 300 and 600 A/m². High current density helps

to increase deposition rate and reduce concentration polarization problems.

Electrolyzer capacity: Common design capacity is generally around 5 to 10 liters,

which can be customized according to production scale.

Electrolyte circulation flow rate: usually in the range of 400 to 700 L/h to ensure

high-speed circulation of electrolyte and optimize mass transfer effect.

Operating temperature: controlled between 25℃ and 60℃. Different metals may

require slightly different temperature settings to achieve the best reduction effect.

video

Call us now: