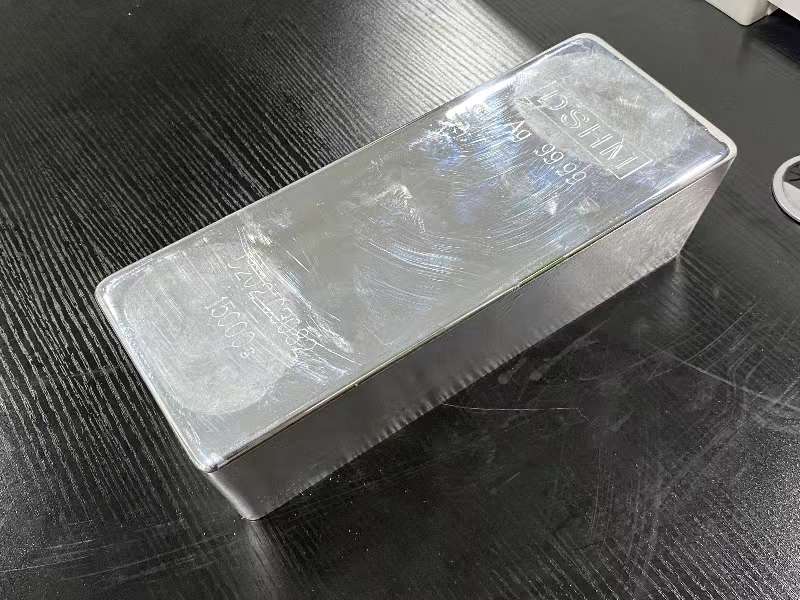

Thailand - Fully automated silver ingot refining

The fully automated silver ingot refining equipment adopts an intelligent

integrated design, actively integrating key processes such as mold preheating,

silver ingot casting, cooling, polishing, weighing and marking. The equipment

actively adjusts the speed control system and high-precision weighing module

to ensure that the silver liquid is stable and uniform during the solidification

process, and the weight error of each ingot is kept within 1%.

At the polishing station, the equipment uses a visual recognition system to

detect and correct defects on the surface of the silver ingot in real time, and actively

controls the roughness to be below Ra0.8μm. At the same time, the built-in dynamic

sensor and AI algorithm continuously feed back data to the central control system

to ensure that each ingot product meets the delivery standards of the Shanghai Stock

Exchange.

Relying on the "unmanned operation + closed-loop management" mode, the

equipment actively produces 300 to 400kg of silver ingots per hour and reduces the

silver loss rate to less than 0.05%. The modular design supports rapid changeover

and is suitable for the production of high-purity silver ingots of more than 99.99%,

thus setting a new benchmark for high precision, low energy consumption and

intelligence for the precious metal refining industry.

Call us now: