Call us now:

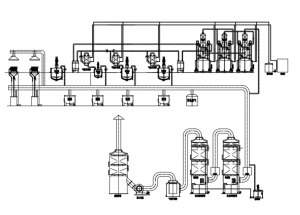

With the joint efforts of the scientific researchers of Zhengzhou Jinquan Mining and Metallurgical Equipment Co., Ltd, we have changed the way of NOx treatment. The flue gas from the reactor first passes through the vapor-liquid separator, so that the liquid beads are effectively returned to the reactor, and the gas is converted into salts or harmless gas after the forced gas-liquid mixing device; the NOx treatment process realizes the full recovery of precious metals, and then the trace amount of flue gas passes through the two-stage power wave After the scrubbing tower to meet the standard emission.

a. The high concentration of flue gas from the reactor is first condensed to achieve gas-liquid separation, and the acid and precious metals contained in the liquid flow back into the reactor.

b. The acidic gas after gas-liquid separation enters the flue gas bubble adsorption tank, where the gas easily soluble in the agent reacts with the agent.

c, incomplete reaction of the gas into the vertical vacuum injection system and the reaction of the agent in the tank to generate nitrogen and water.

d, in this first stage of the jet absorption tank is replenished with oxygen (air) and NO reaction to generate NO2, into the next stage of the jet scrubber tower again reaction;.

f, at this time, NOx is basically completely absorbed by the above three-stage absorption device into nitrogen and water, and then into the two-stage absorption tower and a carbon adsorption device to meet the emission standards.