Call us now:

1、SCR low-temperature catalysis:using V2O5-WO3/TiO2 as catalyst, flue gas temperature 280℃~400℃;

2, SNCR process: processing high temperature flue gas from 930℃~1100℃, both of the above are for high temperature flue gas from pyrometallurgy.

3, high temperature carbon reduction:flue gas is passed into the burning coke layer to generate nitrogen and carbon dioxide, thus meeting the emission standards, but the labor intensity is high, and brings new problems such as excessive dust in the flue gas and poor operating environment.

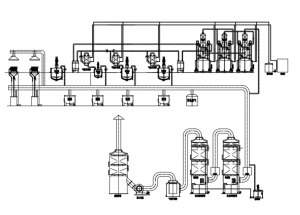

For the reactor wet reaction generated by nitrogen oxide fumes: our nitrogen oxide treatment equipment using jet jet tower multi-stage tandem used to deal with nitric acid de-hybridization or gold soluble in gold by gold jet jet tower is characterized by rapid circulation of pharmaceuticals to create a vacuum in the pipeline, so that the slightly negative pressure state of the reaction kettle nitrogen oxide fumes through the jet tower inhaled by the jet forced to break up, following the jet After a multi-stage tandem reaction, the nitrogen oxides are converted into nitrogen gas to meet the emission standards.