Call us now:

Capacitors as one of the main components of electronic and electrical products. With the generation of a large amount of electronic waste, the generation of waste capacitors has increased dramatically, which contains metal components that can be resourceful, so the resourceful recycling of waste capacitors has become a key concern, as domestic regions, especially in Guangdong, a large amount of electronic waste is eliminated every year, waste capacitors are part of the electronic waste.

Capacitors are electronic components of circuit boards. Capacitors are mostly composed of PET film or PP film, iron pin (also called electronic foot, outer layer of tin plating and inner layer of copper plating), aluminum foil and outer layer of red or green lacquer case. After the equipment processing, it is concluded that there are about 30% of aluminum sheet, iron pin, black rubber head, oil paper and plastic in the capacitor, which can be reused after sorting out by environmental protection treatment, so the recycling value is great. The recycling value of waste capacitors is great, and the waste capacitors can be refined into aluminum ingots.

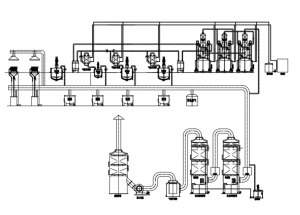

Process flow: Multi-knife crusher crushes and decomposes the waste capacitors; Specific gravity sorting machine carries out wind and specific gravity sorting of the crushed capacitors to separate out the oil paper and separate out the aluminum, rubber and electronic feet; Magnetic separator carries out magnetic separation of the materials after specific gravity sorting to separate out the electronic feet magnetically; Eddy current sorting machine separates out the aluminum and rubber. Waste capacitor - multi-knife crusher - wind specific gravity sorting machine - eddy current sorting machine - aluminum and paper, plastic.

Product advantages: 1、The core technology is the organic combination of special crushing, crushing and dissociation equipment for various waste electronic components and capacitor components to achieve greater energy saving in the production process, and to achieve a high metal separation rate.

2、Advanced mechanical crushing, crushing, specific gravity sorting, high-voltage electrostatic separation of the new process, crushing and dissociation of metal and non-metal materials after the separation, the degree of high.

The basic structure of different kinds of capacitors, their composition characteristics, resourcefulness value and possible harmful components; aluminum capacitor is made of aluminum cylinder as negative pole, liquid electrolyte inside, and inserted a piece of bent aluminum tape as positive pole. While aluminum capacitors are growing steadily in the traditional consumer electronics field, their application fields are expanding with structural transformation and technological progress in many emerging fields such as energy-saving lamps, inverters and new energy.