Call us now:

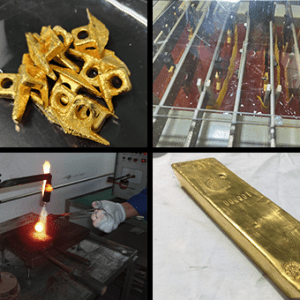

1、Prepare electrolyte: use the gold dissolving equipment in the process of aqua regia method to prepare gold electrolyte, take 99.99% gold powder, add aqua regia, make it fully dissolved, after the dissolution is finished, filter the insoluble residue, the solution is added to the electrolytic bath.

2、Melt and cast anode plate: use the raw material containing more than 92% gold to melt and cast the anode plate using medium frequency furnace and hang it in the designated position of the electrolyzer.

3、Gold electrolysis: After hanging the anode plate, turn on the electrolysis, inspect it from time to time, add 2:1 hydrochloric acid solution to keep the electrolytic tank level; after the electrolysis is finished, turn off the electrolysis, take out the cathode plate, collect the gold pieces precipitated on the cathode plate and send it to washing, then take out the anode bag, wash the residue and anode bag; after washing and drying, send the gold powder to granulation, drying, ingot casting and marking process, and send it to the gold warehouse after finishing; after use, the residue is returned to the smelting workshop for washing. The residual electrode is returned to the smelting workshop for melting and casting gold anode plates; the anode sludge produced in the process is sent to the wet refining system for platinum group metal recovery.